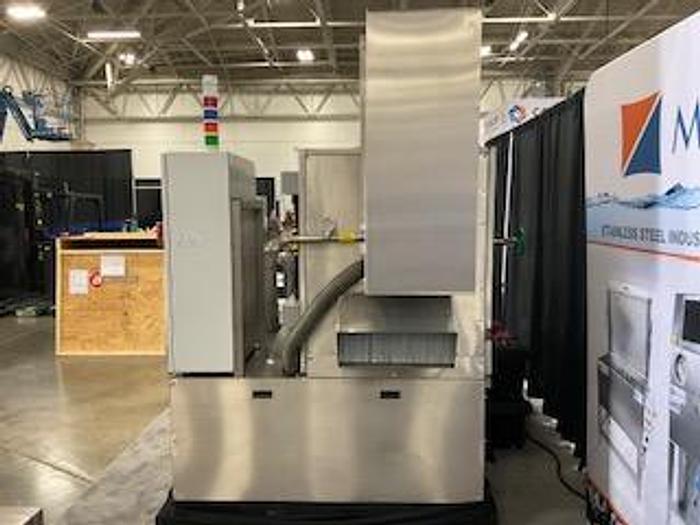

S-640 Rotary Drum Parts Washer/Dryer

S-640 Rotary Drum Parts Washer/Dryer

$119,500 (USD)

Description

2 STAGE ROTARY DRUM WASHER/DRYER

Rotary Drum Parts Washing System

- Soak/Immersion Wash

- Spray Wash

- Heated Dryer

Series: SPIRA

Model: SP-640

MAGIDO rotary drum parts washers are perfect for continuous cleaning & drying of high volume, small parts when part-on-part contact is acceptable. In operation, as parts auger through the machine’s processing drum, they are first submerged in cleaning solution, spray-washed, followed by an optional heated drying or blow-off stage. These units are a complete feed-thru operation, which allows for parts to be automatically fed the cleaning process.

SP-640 Standard Features

- Stainless Steel Construction

2. Rotational Drum with Auger and Speed Control (Stainless Steel)

3. Spray Manifold with Optimized Wash Nozzles (Stainless Steel)

- Removable Isolation Floor and Lift Out Chip Basket (Stainless Steel)

- Electric Tank Heaters with Digital Thermostat Controller

- Vertical Stainless Steel Pump

- Siemens PLC Control

- Steam Exhaust Fan (Stainless Steel)

- Tank & Cabinet Insulation

- Liquid Level Shutoff with Automatic Water Fill

(Stainless Steel: AISI 304 Grade)

Sequence of Operation

1. Load Parts: Manual

2. Immersion Wash: Immersion Agitation

3. Spray Wash: Spray Wash Agitation

4. Drain: Excess Water Returns to Wash Tank

7. Air-Knife Blower Removal of Excess Water

8. Heated Dryer: Dry Parts

9. Parts Offload: Parts Exit Down Slide Ramp

SP-640 Technical Specifications

Working Envelope

Drum Length 98.4”

Drum Diameter 25.2”

Thread Pitch 7.9”

Thread Depth 4.7”

Drum Holes 0.5 CM

Part Load Height 57.9”

Part Offload Height 28.3”

Production Volume 12.7 CF/H

Wash Tank

Fluid Capacity 145 Gal

Pump Power 4 HP

Pump Pressure 43 PSI

Pump Flow Rate 90 GPM

Drain 1 ½”

Electric Heater 24 kW

Rotational Drum

Gear Drive ¾ HP

Speed 0.6-3.8 RPM

Speed Controller Standard

Potentiometer Standard

Steam Exhaust Fan

Fan Power ¼ HP

Flow Rate 180 CFM

Electric Heated Dryer

Heating Power 15 kW

Temperature Range 100-210 °F

Fan Power 1.5 HP

Fan Flow Rate 700 CFM

Power Requirements

Voltage 460V/3PH/60Hz

Control Voltage 24V/AC

Overall Dimensions

Width 87.8”

Height 87.4”

Length 135.8”

Dry weight 2,650 lbs.

Technical Specifications Parts Washer Options

Drain Pump (Option)

Power 0.75 HP

Pressure 30 PSI

Flow Rate 20 GPM

Regenerative Air-Knife Blower (LSS7.5) (Option)

Fan Power 10 HP

Flow Rate 365 CFM/5.8PSI

Oil Skimmer (Option) Stainless Steel Disc

OS-170 Oil Coalescer (Option)

Constriction AISI 304 Stainless Steel

Flow Rate 8 GPM

Tank Capacity 45 Gal

Pump Power 1/3 HP

Pump Pressure 6 PSI

Flow Rate 14 GPM

External Dimensions L30” x W32” x H53”

S-640 Standard Design Specifications

Construction: The cabinet, solution tank, rotational drum are manufactured in AISI Grade 304 stainless steel.

Rotational Drum: The drum is designed with perforated stainless steel sleeve and internal spiral auger to index the parts through the wash process. The rotational drum is powered by a gear drive with adjustable speed controller

Wash Stage: In operation, as parts auger through the machine’s processing drum, they are first submerged in cleaning solution, spray-washed with vee-jet wash nozzles.

Electric Heating Elements: A thermostat controller allows the operator to adjust the heat setting to achieve the desired operating temperature. Heating elements will automatically cycle on/off to maintain the set temperature (Ambient-180 °F).

Fluid Level Control: A level sensor actuates a solenoid valve when the solution level is low, allowing water to enter the machine. The pump and heat source will shut off to prevent damage until solution reaches adequate levels.

Chip Basket: The isolation floor beneath the turntable prevents parts from falling into the holding tank and channels the solution into a lift out chip basket.

Tank Cleanout Features: To expedite the solution change out process, the machine is equipped with a marine style cleanout door, lift off tank access panel, and tank drain.

Steam Exhaust Fan: The exhaust fan located in the ceiling of the tunnel operates continuously to remove steam any buildup.

Electrical Panel: 24V/AC control voltage with Siemens PLC (LOGO), illuminated pushbutton controls, lights, standard overload protection, and rotary power disconnect switch. (IP 55, RAL painted)

Safety: Emergency Stop button are located at the tunnel entrance and exit areas.

Thermal Insulation: The solution tank and process tunnel are insulated with 1.5” of insulation material and covered with stainless steel panels.

CUSTOM SIZED DRAIN PERFORATIONS

BAG FILTER COLUMN W/ MAINTENANCE

INDICATOR LIGHT

REGENERATIVE AIR KNIFE BLOWER (10HP)

OS-170 OIL WATER COALESER FUTURE USE CONECTION

CONTINUOUS WELDS THROUGHOUT DRUM

Specifications

| Manufacturer | Magido |

| Model | S-640 |

| Year | 2022 |

| Condition | New |